Different Types of Dust on Solar Transmittance and PV Performance

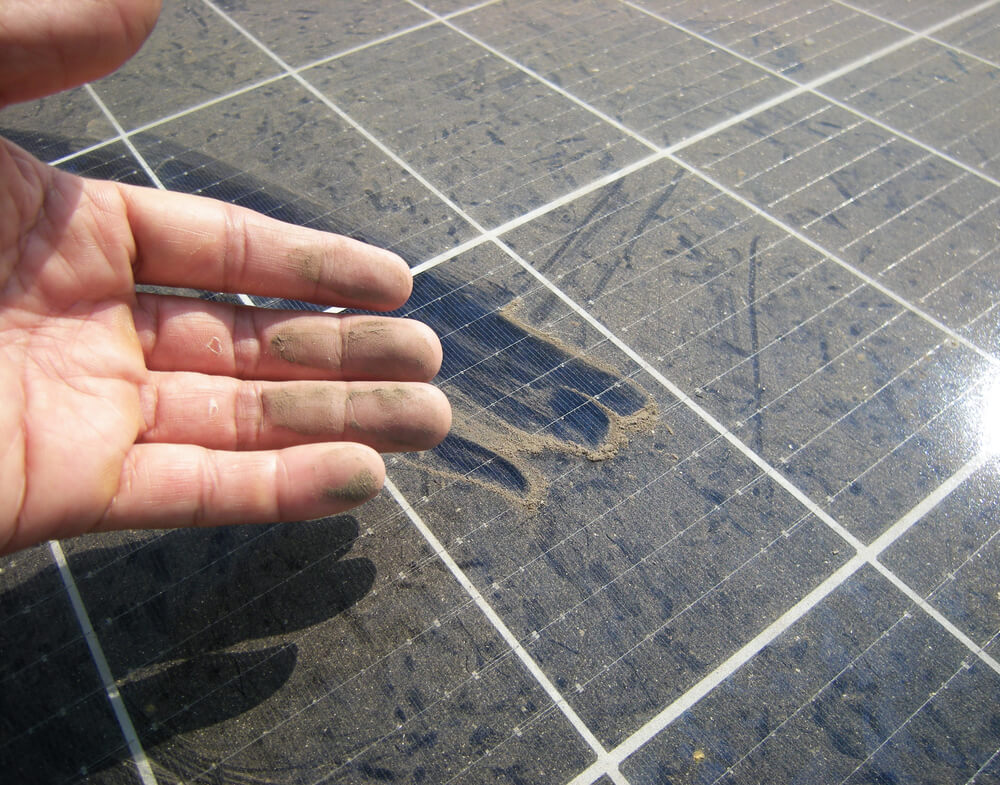

Dust accumulation on photovoltaic modules is one of the most persistent and underestimated challenges in solar energy systems. While it’s common knowledge that dust reduces solar transmittance and energy yield, the type of dust—not just the amount—plays a critical role in determining the severity of performance degradation, cleaning frequency, and even long-term module damage. To ease this problem, a solar panel cleaning service is in high demand.

This article examines the diverse types of dust, their distinct impacts on PV modules, and effective mitigation strategies, offering field-proven insights for those in need.

Why Dust Type Matters

Dust isn’t a homogeneous material. Its chemical composition, grain size, stickiness, and abrasiveness differ based on the environment:

- Industrial zones may have metallic or chemical-laden dust

- Coastal regions face salt spray and sea aerosols

- Deserts deal with fine, silica-based dust

- Agricultural areas encounter organic, pollen-rich dust

- These differences lead to different physical and chemical impacts on PV surfaces.

Types of Dust and Their Impacts

| Dust Type | Common Regions | Key Characteristics | Primary Impacts on PV Modules |

|---|---|---|---|

| Silica Dust (Desert Dust) | Arid zones, deserts | Fine particles, high abrasiveness | Reduces transmittance, causes micro-scratches, may erode anti-reflective coating |

| Saline Dust (Sea Aerosols) | Coastal areas | High salt content, hygroscopic | Causes corrosion of frames and junction boxes, attracts moisture, can trigger PID |

| Industrial Dust (Carbon, Soot, Chemicals) | Factories, urban centers | Sticky, chemical-laden | Strongly adheres to glass, may react with coatings, requires specialized cleaning |

| Organic Dust (Pollen, Plant Debris) | Farmland, forests | Lightweight, often sticky | Forms biofilms with moisture, accelerates fungal growth, reduces light capture |

| Volcanic Ash or Fine Particulates | Near volcanic areas or wildfires | Sharp, microscopic particles | Highly abrasive, dangerous for glass surfaces, may require full module rinsing |

Dust Reduces Solar Transmittance

Solar transmittance refers to how much sunlight can pass through the glass surface of a solar panel and reach the photovoltaic (PV) cells underneath.

| Dust Type | Transmittance Reduction |

|---|---|

| Light, dry dust (e.g., desert dust) | 5%–15% |

| Sticky, chemical or organic dust | 10%–25% |

| Salty or wet-cohesive dust | Up to 30% or more |

Dust Degrades PV Module Performance

Dust doesn’t just block sunlight — it affects energy conversion and system reliability.

| Impact | Description |

|---|---|

| Reduced Power Output | Less sunlight = less energy generation. Performance Ratio (PR) can drop by 5% to 35%, depending on dust type and thickness. |

| Hot Spots | Uneven dust buildup causes partial shading, which increases resistance and leads to localized overheating. This can damage cells or bypass diodes. |

| Voltage and Current Drop | Dust shading leads to lower short-circuit current (Isc) and sometimes affects open-circuit voltage (Voc), especially under light-sensitive conditions. |

| Chemical Interaction | Salty or industrial dust can corrode connectors, frames, or coatings, further reducing output over time. |

| Soiling Losses | Defined as the difference between expected and actual energy due to surface contaminants. It varies by location, weather, and dust type. |

Performance Implications

Energy Yield Loss: Depending on the dust type and location, efficiency can drop by 5%–35%.

Hot Spots: Uneven accumulation (e.g., bird droppings + dust) causes localized shading and hot spots.

Permanent Damage: Saline or chemical dust can corrode frames, glass, or bypass diodes over time.

Cleaning Cost and Frequency: Stickier or abrasive dust types require more frequent or gentler cleaning methods, impacting O&M budgets.

Tailored Mitigation Strategies

| Dust Type | Recommended Solutions |

|---|---|

| Silica Dust | Use anti-soiling coatings; schedule soft-brush or air-blowing cleanings; consider robotic dry-cleaners |

| Saline Dust | Use corrosion-resistant frames and junction boxes; apply hydrophobic coatings; rinse with deionized water |

| Industrial Dust | Install filters near urban plants; schedule water-based cleaning with mild detergents |

| Organic Dust | Use biocidal coatings; ensure good tilt angles for natural runoff; regular moisture-free cleaning |

| Volcanic Ash | Use ultra-soft brushes or air blowers; avoid dry wiping; rinse gently to prevent micro-scratches |

How to Clean Different Types of Dust on PV Modules

| Dust Type | Cleaning Method | Tools/Agents | Precautions |

|---|---|---|---|

| Silica Dust (Desert Dust) | Dry or wet cleaning depending on layer thickness. Use air blowers or soft-bristle brushes for loose dust. Use deionized water for caked-on dust. | - Anti-static soft brush- Low-pressure air blower- Deionized water (DI)- Robotic dry cleaners | Avoid abrasive scrubbing, especially on dry glass. Fine silica can scratch the anti-reflective coating. Always rinse before wiping. |

| Saline Dust (Sea Aerosols) | Wet cleaning only. Use deionized water to dissolve salts. Avoid dry brushing, which can embed salt into surface. | - Deionized water- Soft microfiber mop or sponge- Anti-corrosion rinse additives (optional)- Soft low-pressure sprayer | Never use tap water, which may add more minerals. Rinse thoroughly to prevent salt streaking and corrosion. |

| Industrial Dust (Carbon, Soot, Chemicals) | Wet cleaning required. Use mild detergent or specialized PV cleaner to remove sticky/greasy layers. | - Non-ionic PV-safe detergent (pH 6–8)- Soft sponge or mop- DI water rinse- Rubber squeegee | Avoid strong alkaline/acidic cleaners. Test detergent on a small area first to ensure no reaction with coating. Clean early before soot hardens. |

| Organic Dust (Pollen, Plant Debris) | Use moist microfiber cloth or rinse with water. For sticky pollen, apply water and wait 5–10 mins before wiping. | - DI water- Soft microfiber cloth- Soft rubber squeegee | Clean during cool hours (early morning/late evening). Avoid wiping dry pollen which can stick more with static charge. |

| Volcanic Ash / Fire Residue | Never dry clean. Ash is highly abrasive. Always pre-rinse and allow ash to soften before light wiping. | - DI water spray- Ultra-soft brush- No-pressure water jets- Avoid cloths unless fully rinsed | Ash can microscratch the surface. Use extreme care. Flush first, then gently lift off remaining residue. Avoid pressure washers. |

While dust is an inevitable environmental factor for solar PV systems, its impact is far from uniform. The type of dust—its composition, texture, chemical properties, and behavior—directly influences how it affects solar transmittance, energy yield, and even long-term module integrity.

Recognizing these differences empowers solar companies to adopt more precise cleaning strategies, preventive designs, and monitoring systems, ultimately leading to lower operational costs, longer system lifespan, and improved return on investment.

Post time: Jul-01-2025